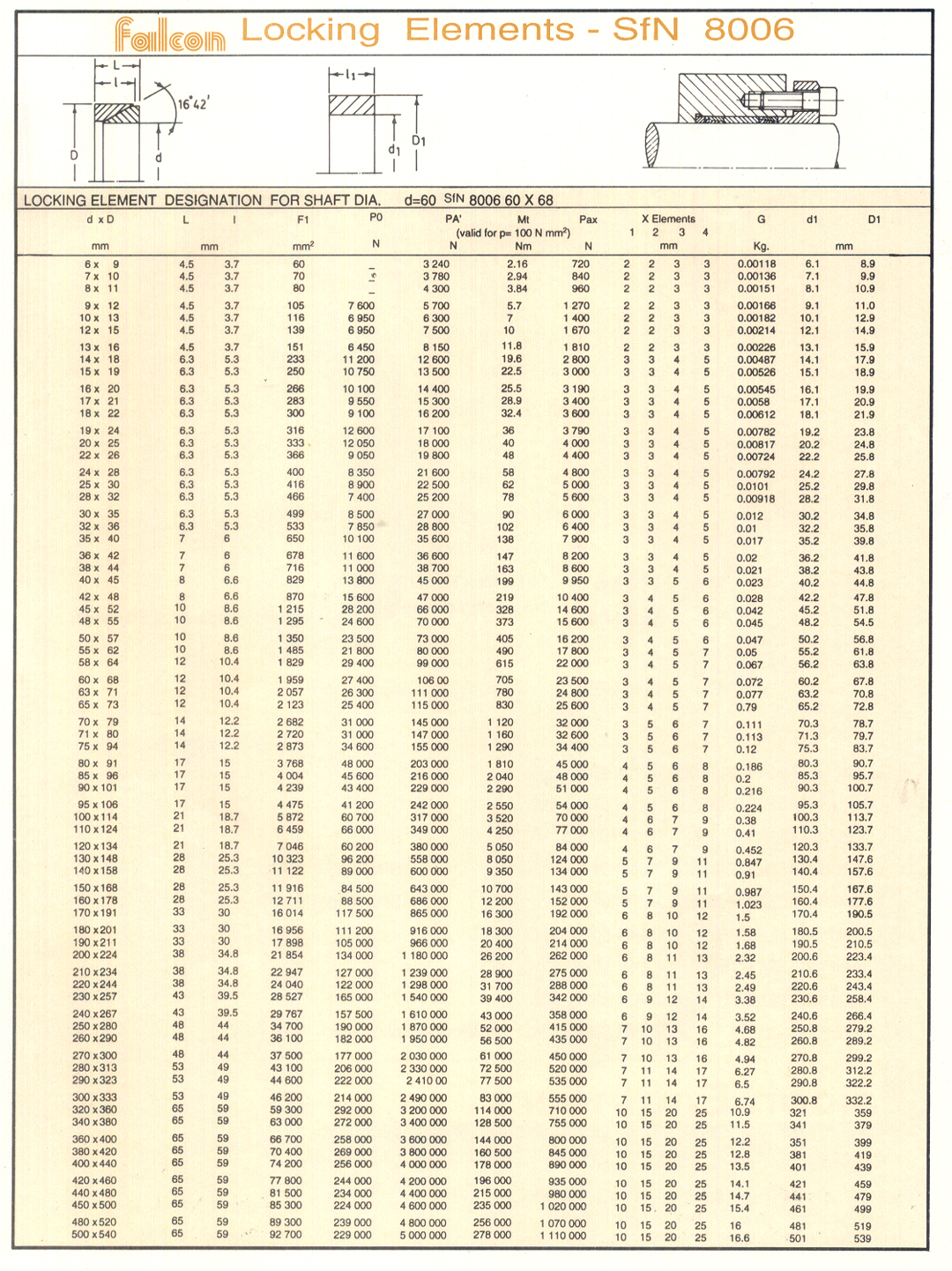

LOCKING ELEMENT [ SFN 8006 ]

Key Tags

-

-

Locking Element

-

Locking Element Manufacturer

-

Locking Element Supplier

-

Locking Element Exporter

-

Locking Element India

-

-

Locking Element Gujarat

CONSTRUCTION HINTS

General Information For The Use of Elements :

| Surface finish for shaft & hub : | Rt < 6 mm. | |

| Shaft | Hub | |

| Tolerance Recomanded : up to 38 | h6 | H7 |

| above 38 | h8 | H8 |

| Friction Coefficeient | M = 0.12 for slightly oiled Locking Elements. | |

| Mtot = 0.14 for Locking Screws. | ||

| General forque : Mt = 9560 P/n (Pin kw) = 7026 P/n (Pin H.P.) | Mt1 = Mt x Factor of Safety No. of elements required = Mt1/Mt (torque capacity of Elements) | |

| -P = Power n = RPM of driven part | ||

Locking element is special component used in shafts to transmit the torque to-and-from the shaft in various ways according to the application. The locking element consists of internal and external tapered ring. Some applications also stack the elements to get greater torques. As locking element manufacturer, we provide them in various dimensions as per the industry set standards. The element is composed of two different halves, one is joined through bolts and other has a slit for contraction.

The bolts are tightened according to the sequence and the torque setting of the shaft. As the pressure between the locking element and shaft rises, the internal diameter of element decreases. We are located in Gujarat, but we offer our locking element not only in Gujarat but also export them in Indian states and in global market.